Type : ALC Thin Mortar

Product : Mortar

Colour : Grey

Weight : 40.00kg

Packing : 50Bag/Pallet

Min Order Per : 1 Bag

Cement-based premixed mortar for thin jointing of ALC Blocks passing Fire Test BS 476.

E.MIX ALC THIN MORTAR is a high quality water resistant premixed mortar for the laying of Autoclaved Lightweight Concrete (ALC) blocks. It is specially formulated for filling of vertical and horizontal joint for ALC wall system.

Uses

- Masonry for ALC blocks

Features and Benefits

- Fire resistance of over 260 minutes at 1,300 °C

- Shrinkage compensated: reduce the chance of shrinkage cracks

- Single component: fixed mixing proportion, ensure the quality of work

- Thin layer application: less consumption of mortar

- Good levelling of wall: prevent descend of blocks

- High water resistance

Procedures

Substrate Preparations

- All substrates should be firm and clean. Substances that weaken the bond such as dust, oil, loose particles and impurities should be removed from ALC block receiving surfaces.

Mixing and Installation

- Mix one bag (40 kg) of E.MIX ALC THIN MORTAR in approximately 14.4 litres of clean water. Use of electrical hand mixer is recommended. Allow mixture to stand for 10 minutes. Mix again and the joint mortar is ready for use.

- Ensure that joint of ALC blocks are fully covered with the joint mortar using a notched trowel. Blocks should be jointed before film is formed on the surface of the E.MIX ALC THIN MORTAR. Completed joints should be approximately 3 mm thick.

- Upon laying of ALC blocks, immediately remove excess joint mortar from the surface of the joint before it sets. ALC wall should be laid to the correct alignment so that thin plasters can be applied on the completed wall internally. Allow the joint mortar to set and harden for at least 24 to 48 hours to achieve its initial bond strength.

Curing

Natural air curing is enough for E.MIX ALC THIN MORTAR. Water mist is not required for interior application. However, water mist is required under extremely hot or dry condition.

Storage and Packing

E.MIX ALC THIN MORTAR is delivered in 40 kg bag.

Storage life is 6 months if the product is stored in a dry place.

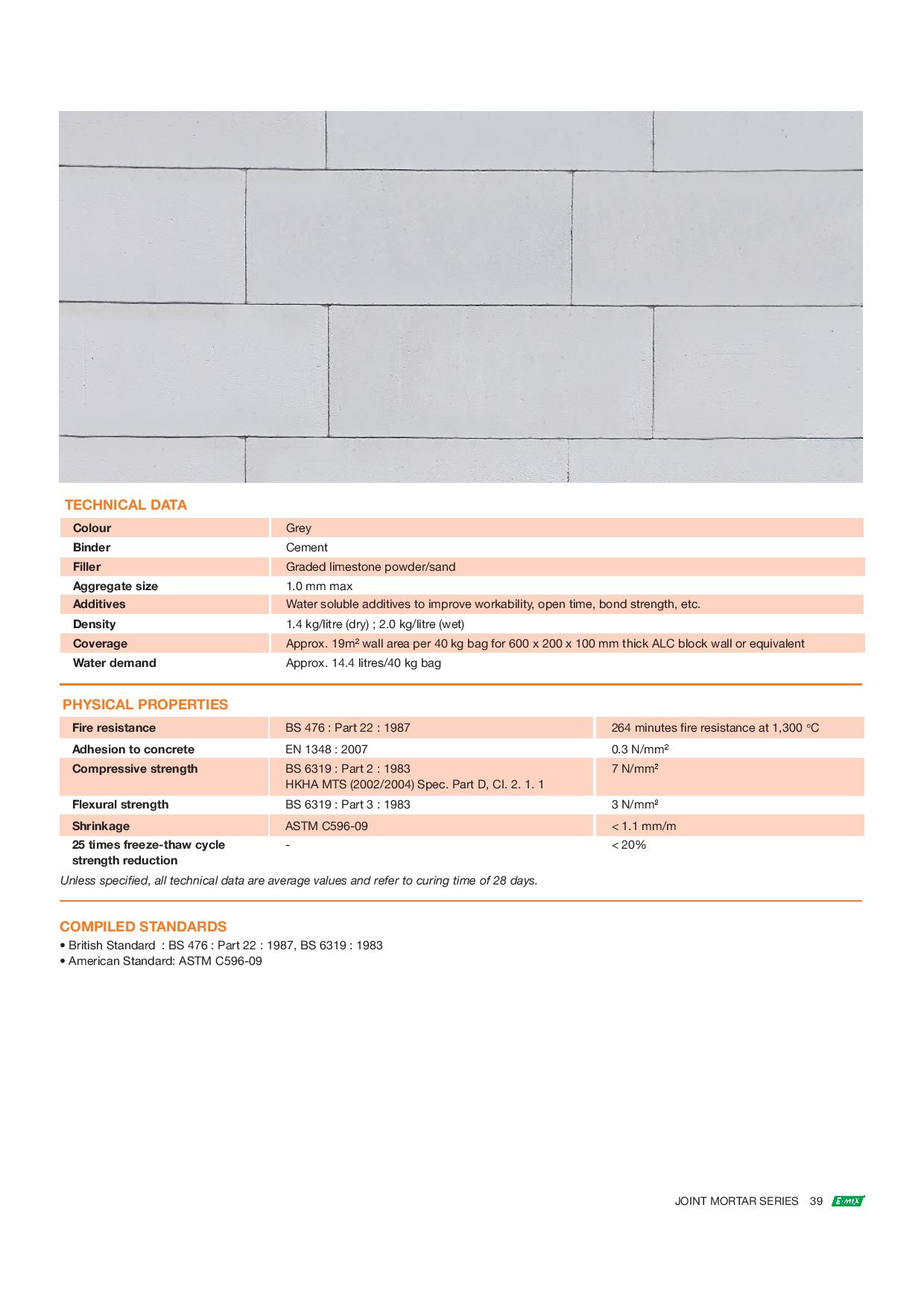

Technical Data

| Colour | Grey | ||||||||||

| Binder | Cement | ||||||||||

| Filler | Graded limestone powder / sand | ||||||||||

| Aggregate size | 1.0 mm max | ||||||||||

| Additives | Water Soluble Additives to Improve Workability, Open Time, Bond Strength, etc. | ||||||||||

| Density | 1.4kg/litres (dry) ; 2.0kg/litres (wet) | ||||||||||

| Coverage | Approx. 19m² wall area per 40 kg bag for 600 x 200 x 100mm thick ALC block wall or equivalent | ||||||||||

| Water Demand | Approx. 14.4 litres/40 kg bag | ||||||||||

Physical Properties

| Fire Resistance | BS 476 : Part 22 : 1987 | 264 minutes fire resistance at 1,300 °C | |||||||||

| Adhesion to concrete | EN 1348 : 2007 | 0.3 N/mm² | |||||||||

| Compressive strength | BS 6319 : Part 2 : 1983 HKHA MTS (2002/2004) Spec. Part D, CI. 2. 1. 1 | 7 N/mm² | |||||||||

| Flexural strength | BS 6319 : Part 3 : 1983 | 3 N/mm² | |||||||||

| Shrinkage | ASTM C596-09 | < 1.1 mm/m | |||||||||

| 25 times freeze-thaw cycle strength reduction | – | < 20 % | |||||||||

Unless specified, all technical data are average values and refer to curing time of 28 days.

Complied Standards

- British Standard : BS 476 : Part 22 : 1987, BS 6319 : 1983

- American Standard: ASTM C596-09